Introduction to Winching

Winch with flat-link. Image courtesy of Warn Industries-Factor 55

Winches adhere to Murphy’s Law. If you have one, odds are that you will not need it. Don’t have one, and you will get stuck and wish that you had one.

Besides looking really cool at the mall, a good winch can get you or a fellow offroader unstuck on the trail. Winching is the solution if you are high centered on a rock, unable to get up a steep hill, or have slid off the trail down a slight embankment.

Unlike a kinetic recovery, where another vehicle catapults you free from being mired down in mud, sand, or snow – winching is a slow and steady pull.

Generally, if a kinetic yank can free a vehicle that has lost tire traction, it is quicker and simpler just to grab a couple soft shackles and attach a kinetic line to both vehicles. The first kinetic pass should have the recovering vehicle positioned with 5 feet of slack, and slowly drive forward at 5mph. If that fails, then do 10 feet of slack, but still not faster than 5mph. If those attempts fail, do NOT try more aggressive kinetic pulls; it is now time to use the winch.

For vehicles high centered on rocks, or struggling to make it up a hill, or partially down an embankment – you want the slow and steady control that a winch affords. Forceful kinetic jerks could easily cause damage in those situations.

The caveat to winching is that you need something to attach the other end of the winch onto.

In the desert regions out here in Nevada and Utah, that can be a serious problem if you are out by yourself. Cactus and desert shrubs cannot support a Jeep. Sand dunes offer nothing. So a winch is only useful if you have big trees or boulders to anchor to.

“NEVER go out without at least two vehicles. With a second vehicle, you have something to attach your winch line to. So long as one vehicle has a winch, both of you are covered.”

What size winch should you purchase?

Common recreational winches are rated from approximately 5000 to 12000 pounds. The smaller sizes are for UTV’s and side by sides. The larger sizes 9000-12000 are generally for our 4x4 vehicles.

The rule of thumb is that your winch should be rated roughly twice the weight of your vehicle. Wranglers weigh approximately 4000-4500 pounds, so the winch should be rated at least 9000 pounds. Toyota 4Runners are slightly heavier, at 4700+ pounds, so a 9000-10,000 pound winch should still be sufficient.

Larger winches may be needed for pickup trucks.

We normally do not purchase the largest capacity winch on the shelf, on account of their size and weight. Mounting a 12,000 rated winch on the front bumper of a Jeep contributes to being front heavy.

A winch is only as strong as your bumper and your rear recovery point. Whatever force your winch is able to generate must be properly anchored by the mounting system to your chassis; a few flimsy bolts or a dirty weld will not suffice. To keep the winching vehicle from being the one pulled, you may need to anchor the back of your vehicle to something heavy or another vehicle. That requires a secure rear shackle or hitch receiver.

Only the most extreme recovery operations would require enormous pulling power. Under those conditions, unless you are driving a custom recovery wrecker, it is more prudent to utilize multiple vehicles with multiple winch lines.

It is easy to double the effective pulling force of a winch line by using a pulley arrangement, such as a snatchblock or donut ring. That would make a 9000 pound winch into an 18000 pull.

A pulley can double the pulling force of your winch

That’s a whole lot of pulling force! A full 18,000 pounds may be more than your bumpers can realistically handle, while your vehicle is being stressed both front and rear – because unless the winching vehicle is anchored, it will be the one moving.

However, that does not mean that you will be exerting a full 18,000. If the situation is so dire that it requires that much pull, you probably don’t have the experience to attempt that complex of a recovery. Most likely, though, a few thousand pounds should suffice for most simple trail recoveries.

Another factor to keep in mind is that the more wrap layers of line remaining on the winch spool, the less pulling force is generated. They say that you lose around 15% of leverage for every added layer wrapped on the drum. To max out your pulling strength, you want to unspool most of your line so that you are on the first wrap. That is not always practical, but the use of a pulley (double pull line) will provide twice the pull strength while using up more of your overall line.

Steel braid or synthetic line?

Winches traditionally always came supplied with steel braided line. Steel line is extremely strong and very hard to damage, especially if dragged across dirt or rocks. Synthetic line is softer and has a lower breaking point. It is more easily frayed and damaged when dragged across rough surfaces. Metal edges can cut through it. Synthetic line costs a bit more, and requires occasional cleaning.

However, the offroad community currently prefers synthetic over steel. Steel, for all its advantages, has one HUGE disadvantage – it retains potential energy. Under the heavy tension of thousands of pounds, should one end connection fail – that steel wire will whip violently. It will do significant damage to anything and anybody within its travel arc. Serious bodily injury. Any metal object at its endpoint -- such as a heavy hook, D-ring shackle, or a tow ball -- may be catapulted back into a windshield like a cannon ball. No, I am not exaggerating; there have been several documented fatalities!

On the other hand, when synthetic line fails – it just plops to the ground.

Must-have winching accessories

In addition to a professionally installed winch, there are a few things to add to the checklist.

A good winch fairlead. The fairlead or fairing is the frame that fronts the opening through which the winch line passes. It needs to be rounded and perfectly smooth. Any burrs or flaws will fray a synthetic line. If your winch originally was equipped with steel line, you should polish or replace the fairlead.

Factor 55 winch fairlead and pro-link closed winch line endpiece

A secure winch line endpiece hook or shackle. The older style open J-style winch hooks may not be certified strong enough, or slippage could cause the opening of the hook to slip off. Improved hooks feature a thin metal trapdoor guarding the opening to prevent total slippage, but should too much angled tension somehow exert against the trapdoor – the hook will fail. Some imported hooks are not certified and cast from weaker metal. Only select hooks from reputable sources!

A very popular arrangement is closed system winching. Instead of having open J-hooks, the end of the winch line is a closed O-style metal shackle. Soft shackles or metal D-ring shackles are used with it to make secure connections.

Factor 55 offers a combination endpiece that features both an open hook and a closed shackle in the same unit.

You will need a remote control device to operate your winch. Corded units offer the best reliability and should be long enough to easily reach back to the drivers compartment. There are also wireless remotes. Wireless allows for control by an observer or recovery director outside of the vehicle.

Wireless systems, often sitting unused for months in the trunk, may require batteries or charging. Take them out and check them on a regular basis. My advice is to keep a corded remote as a backup.

“Store your winch controller in the drivers compartment, rather than deep in the trunk. Sometimes you get in a predicament where you cannot open your tailgate.”

Gloves are essential. Steel cables develop burrs or minor frays and will shred your hands as you tug or guide the line. Synthetic can pick up stray debris and can also damage your palms. Always wear gloves when handling winch lines!

First aid kit because you thought you didn’t need the gloves.

Soft shackle attached to receiver hitch

Line dampers are mandatory with steel lines but can provide a little extra safety around synthetics as well. A winch damper is just a saddlebag or sandbag that you can fill with dirt or rocks and you droop over a taut line. If the line fails, the damper will encourage the tensioned line to fall to the ground rather than to whip wildly. If you don’t have a dedicated dampering saddlebag, feel free to improvise. Rubber or carpet car mats, thick blankets, jackets with weighted pockets – it all helps in case of line failure.

Soft shackles and D-ring metal shackles. These provide connectors for attaching to tree savers or to recovery points on vehicles. Use soft shackles to join soft connections like cloth loops to other cloth loops, or for cloth loops to the rounded side of D-rings. Use metal D-rings to attach to sharp metal edged ringlets that could cut synthetic rope, such as those built into bumpers or receiver hitches and older clamshell snatchblocks.

“Safety is always your number one concern. Keep bystanders far back and way to the side from winch lines. Never straddle a winch line, in case it snaps upward. Only one person is the Winch Director and is the only one giving commands.”

Pretension your winch before heading out

75 or 90 feet of line tangles easily. When you purchased your winch, most likely the dealer only spooled in the line by exerting hand tension. As the winch motor spooled in, they held the line firmly, exerted body strength, and guided the line back and forth so that it wrapped evenly in layers on the winch drum. Make sure that the line spools in from the bottom of the drum, not from the top.

Arm tension is not good enough for long term storage. The proper way to respool a winch line, especially if you are not going to be using it right away, is to pull it in under a lot of tension, like several hundred pounds worth. Like dragging a car.

The proper technique is to literally drag a car. If you have a friend with an offroad vehicle (has to have a recovery hook or a towing hitch receiver), you will winch his vehicle towards yours. Or if you have access to a very secure and heavy duty post or tree, you could winch yourself up to it. Be careful about using street poles and lighting poles; they may appear secure but are often designed to give way if struck by a car, and you certainly don’t want the liability of damaging city property. When in doubt, just find a friend with a car or truck!

The first step is to unspool your line. Winches have knobs to disengage their clutches and to allow free spooling. Disengage your winch and tug out all but several feet of line. Be sure to leave several wraps of the final layer on the drum. It really helps to have a friend keep an eye on the drum as you do the grunt work of walking out the line.

Back the cars away to take up the slack. Do not be holding the line in your hands as you move the cars.

Secure the end of the winch line to the other vehicle. Make sure to connect to a true recovery point, such as a shackle on the bumper, or to a receiver hitch shackle. NEVER to a tow ball.

Remember to re-engage the winch clutch.

Assuming that the vehicle with the winch is to remain static, have the engine running and place the transmission in NEUTRAL (never use the Park setting, because Park has a frail pin that will break under heavy strain). Fully engage the handbrake, and have someone in the vehicle with full pressure on the foot brake.

The other vehicle about to be winched in should also be engine running, transmission in neutral, slight pressure on the foot brakes or manual handbrake set to first or second click. Do not use electronic parking brake. Just provide a little bit of braking to maintain some tension.

Using the winch remote, begin winching in the other vehicle slowly. You don’t want the other vehicle to roll freely or create slack; signal them to apply a little bit of braking for resistance.

Watch your winch line to make sure that it spools evenly and wraps neatly in layers, from one side to the other, and then up one layer and other side back. Think of how a fishing line respools.

Exert a little sideward tension with a gloved hand to insure that the winch line is neatly respooling. Keep your hand at least a few feet from the fairlead; you do not want your fingers caught. You could use a smooth, rounded metal rod or pipe to guide the line instead of it passing through your palm.

Stop and start the winch every 20 seconds or so, so that it does not overheat. Be patient; 75 to 90 feet of line will take a few minutes to spool in.

The reason that you need to retention and respool your winch line is that otherwise the line will birds nest. Synthetic line may shrink or expand over time from temperature change and as it gets wet & dries. This will create little “bubbles” of slack. Later, under tension, the line resting above these “bubbles” will pull down and become wedged inside the lower layers on the drum. As the line ages, these birds nests can become really tight – and knot up when you later attempt to unspool.

Before we learned all of this in a recovery class, my son and I spent half a day vigorously trying to unspool my winch line to clean it (just soap and water and a rag) in preparation. Those birds nests can be extremely hard to unravel, and even can permanently damage the line. If only someone had taught us these things sooner.

Basic types of winching

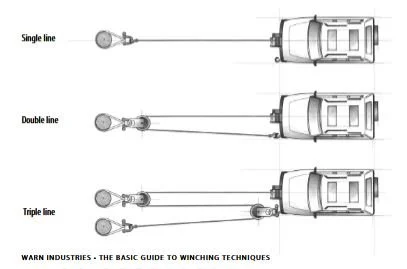

There are three basic techniques for winching:

Single line pull

Double line pull

Redirected pull

Single Line pull

The single line pull is your most basic. The winch line extends in a straight line either to a stranded vehicle or to a fixed anchor.

Image courtesy of Warn Industries. Ultra link winch endpiece

If we are dealing with one vehicle pulling out the other, the steps are as follows:

Disengage the winch clutch, and unspool the line by walking it to the other vehicle. Secure it with a shackle.

The car that remains static should have engine running with transmission in Neutral, and heavy pressure on the brakes.

The car that needs to be recovered should have engine running, and transmission either in Neutral for a completely passive recovery, or in gear (4wd or Reverse, depending on the direction you need to be pulled).

The winching vehicle should increase engine revs to generate more voltage and then begin to winch in the line. Stop and start every 20 seconds or so to avoid overheating the winch.

If you are self-recovering, then attach the winch line to a solid anchor such as a tree or boulder. Use your tree saver strap to protect the tree bark from being circumcised by the winch line. The tree saver strap can be wrapped around a boulder to protect your winch line from being frayed by the rock. Tree saver straps are really inexpensive, compared to having to replace a winch line.

Engine on, transmission in Neutral, and begin winching. Sometimes, you could put your vehicle in 4wd and assist the winching effort. Avoid overtaking and running over your winch line.

Pay attention to the path of your winch line. You want the line to draw straight out from the winch fairlead, and not be tugged at an angle to either side — because that would prevent the incoming line from spooling evenly across the winch drum.

If your winch line is dragging across a rough edged rock or obstacle, the friction could cause it to fray. Many traction boards are designed with full length longitudinal slots or channels that can serve as a smooth pathway for your winch line.

On YouTube there are video showing all sorts of improvised anchors for when there are no trees or boulders. Consider most of those as entertainment only; I have not heard of anyone successfully doing it.

Land anchors are literally boat anchors that are intended to dig into hard soil and provide a place to attach your winch line. Land anchors are bulky, heavy, and take up a lot of storage space. They need plenty of coaxing to get a good purchase and dig themselves in; some terrain just refuse to cooperate.

There are videos of heroes digging large graves and burying entire spare tires six feet under to anchor a line. They don’t show you the backhoe out of frame. Good luck digging through hard packed dirt with just a hand shovel.

There are also videos suggesting that you could stake a hi-lift jack into the ground. And then watch a flying hi-lift jack impale itself through your windshield!

Double line pull

Examples of winch pulls. Image courtesy of Warn Industries

For tougher situations, the double line pull is one of my favorites. Picture a single line pull, but add a pulley at the other end of the winch line and then bring the line back towards the winch.

A double line pull doubles the force of your winch while reducing the speed of the pull in half. More power, but slower. Nothing wrong with that compromise.

Let’s examine the setup in more detail.

There are two types of pulleys: snatchblocks and donut rings.

Snatchblocks are pulleys that have two sliding clamshells over a pulley wheel. You slide open the clamshells, insert your winch line over the wheel, and then slide the covers closed to securely capture the line. When the covers are closed and lined up, there is a ringlet for attaching a shackle. Earlier or traditional snatchblocks were made from stamped metal, with narrow wheels intended for use with steel winch lines and metal D-ring shackles.

There are newer snatchblocks on the market with larger, smoother pulley wheels suitable for synthetic lines and soft shackles.

Donut rings, aka winch friction pulley, are aluminum or metal rounded wheels intended for use with synthetic lines. A soft shackle inserts into the donut hole, allowing the pulley to rotate. The synthetic line is not captured or retained, unlike with snatchblocks. However, Factor 55 offers their unique donut design with rubber fingers that prevent the line from slipping off the ring.

One vehicle recovering a stuck vehicle

Attach either a snatchblock or donut ring to the stuck vehicle. Metal snatchblocks are best attached to the stuck vehicle using metal D-ring shackles, unless they are smooth and rounded enough to be safe with soft shackles. Donut rings are already paired with a soft shackle, so just attach that soft shackle through the D-ring of the bumper shackle.

Sometimes, a tree saver strap is used to share the load with both front bumper shackles; or to provide an attachment point by wrapping the saver around an axle or chassis frame.

Use a receiver hitch shackle; NEVER attach to a tow ball or dropdown.

If the stuck vehicle is being pulled out backwards, then attach the pulley to a rear bumper shackle or use a receiver hitch shackle. Never attach to a tow ball or tow ball dropdown hitch!

Unspool your winch line and walk it up to the pulley system. Loop the line around the pulley wheel, and then secure the pulley in place using soft shackles or D-rings appropriately.

Walk the winch line back towards the winch. Attach the line to one of your bumper shackles.

If the stuck vehicle is heavier than the winching vehicle, or seriously bogged down – the recovery vehicle may need to be anchored in the rear to a tree or boulder, using a tree saver and a towing strap (never a kinetic rope). You could use a third vehicle as an anchor, as well.

However, to lessen the strain on the recovery vehicle, try attaching the winch return line directly to the third vehicle. This reduces the stress on the winching vehicle’s front and rear bumpers. The third vehicle could be parked alongside of the recovery vehicle or directly behind it.

For self recovery, just attach the pulley system with tree saver to a tree or boulder serving as your anchor. Attach the winch return line to your bumper.

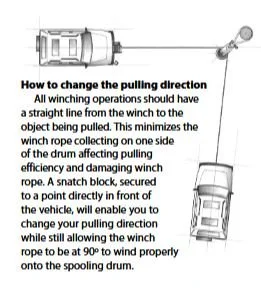

Redirected pull

Image courtesy of Warn Industries

Similar to the double line pull, but in this case we use the pulley system to allow us to change the angle of our winch line. In terms of pulling force, consider it a single line pull, but just not in a single straight line.

Attaching our pulley to an anchor point midway between the recovery vehicle and the stuck vehicle allows us to winch from an off-angle.

For example, one time we were with a group during Winter 4x4, and traveling in a single file caravan along a narrow ledge road. The first few Jeeps passed without incident, but the ledge partially gave way as we drove along. Our driver side front and rear tires slid off of the edge, leaving our Jeep resting on its differential cover with two tires dangling in the air.

The Jeep directly behind us did not have a working winch, but the two Jeeps ahead of us did. They parked side by side, and we used redirects to run two winch lines up to trees and then bring them down perpendicular to our Jeep in order to attach to front and rear bumpers. This allowed them to winch us sideways. Our rear tire caught on the lip of the precipice, so we used a hi-lift to raise the tire high enough to clear. Winched sideways while tipping over the jack to land that tire back on solid ground. No damage to our Jeep, and we continued the trail run unscathed.

Other pulls

Hang out on YouTube for awhile, and you will see examples of all sorts of complex multi-line and multi-pulley arrangements. Unless you are part of a professional recovery organization, leave that crazy stuff for the experts. Triple and quad lines are possible, but make sure that you do all the right math to determine pounds of force on each line and on each anchor point. Yes, with the correct rigging and with high capacity rated components, you could generate almost infinite pulling power –but why would you? The vehicles involved are not inherently strong enough to withstand that much stress.

If you need more winching strength, it is better and easier to just use more vehicles with multiple winches than to quadruple a single winch pull which is way more likely to destroy a stuck vehicle than to rescue it.

“Winching is a serious activity. Make a mistake, and property gets damaged or people get hurt. If the simple and basic techniques don’t work, then call in the experts.”

Cleaning time

After your weekend of fun, don’t neglect winch maintenance. Unspool your line and rinse off any dirt. Then carefully respool the line under tension to prevent future bird nests.

We strongly recommend viewing the two excellent videos and reading the winching tutorial guides provided on the Warn Industries winches website at https://www.warn.com/basic-guide-to-winching-intro Just click the button below.

Note: we were not paid nor rewarded for plugging the folks at Warn/Factor 55. Their stuff is not inexpensive, but it is really the best, and they are legends in the community. We appreciate their permission to use some of their images; and really cannot emphasize how great their company treats the offroad community.